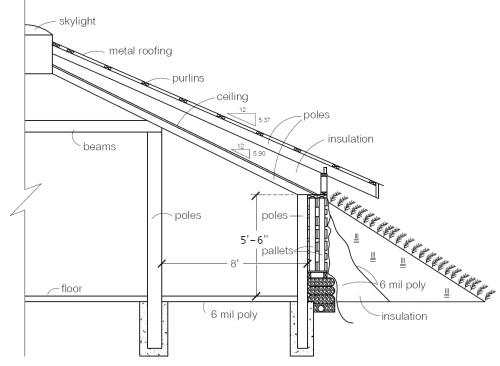

One version of a post and beam pallet wall using girts for added strength to support earth berming. (click to enlarge)

One of the best benefits of doing this blog is having the opportunity to network with other natural builders. Loads (thousands of people) send us info on their projects, ask questions and share their ideas. Some of the best ideas you see on our blog have come about through this brainstorming process. We share them here for the world to see.

A while back I got an email from Rex, a reader who’s planning an ultra-low cost home in Texas. We exchanged a few emails and each time he would ask if it’s possible to further reduce the cost. He said “Owen, I have pallets, cedar poles from my land and dirt.” His persistence in lowering costs had me racking my brain for cost cutting ideas. Rex’s original plan was to build an earth lodge. Now he’s planning a rectangular design that he thinks will be simpler and easier to build. The latest cost estimate for his 800 sq. ft. earth-bermed house design is around $1,600. That’s only $2/sq. ft.! Time will tell if he can actually build at that cost. Lots of small costs quickly add up and you almost always end up spending more than planned. Rex is certainly determined though and off to a good start. He’s already gathered most of his materials and hopes to start soon.

The drawing above shows one possible pallet wall building system, although it differs somewhat from Rex’s design. He has extra strong pallets and doesn’t need girts. He might add a horizontal plate between courses of pallets just to be on the safe side. Most people, however, don’t have access to these unusually strong pallets, and so girts are recommended to help withhold the pressure of an earth berm. (See Pallet Houses and Interior Pallet Walls if you don’t have bermed walls.) The girts also create extra space for insulation, facilitate installation of plumbing and electrical, and serve as nailers for barnwood wall cladding or other materials. And note the horizontal cedar poles at the bottom that the pallets are nailed to. This is a good application of rot resistant cedar wood (juniper), and it demonstrates another way to gain a lot of strength inexpensively.

More from Rex:

“At the moment I’m looking at a 24’x30′ (720 sq ft) post and beam (juniper) earth bermed pallet wall house with clerestory windows and 80 sq ft loft for a total of 800 sq ft. Connected to the loft, access via sliding glass door, will be a deck (100 sq ft.). I may screen it in and turn it into a sleeping ‘porch’. There will be a porch below.

Total cost projections are still up in the air due to the different possibilities for exterior cladding, etc. If one were to take the concept we have discussed, use reclaimed materials for the exterior (pallet planking for cladding or reclaimed sheet metal), earthen plasters or wood cladding for the interior, then one could build at around 2 bucks a sq ft and that includes new sheet metal for the exterior roof. Depending upon which elements we decide to reclaim or buy new the house will cost us between $2-$4 sq ft to build. New items don’t have to break the bank. We got our clerestory windows from Lowes on clearance for $25 per.” [Note: This is common. People order products that they never pick up. Check your building supply stores often for discounts like this! Sometimes there’s just a tiny ding or scratch and the product is drastically reduced in price.]