From time to time we answer reader’s questions. Here, numerous emails have been combined and edited for brevity.

Rex:

My goal is to learn to build houses with local materials in order to help people in my area build sustainable debt free homes. I’m in love with your Earthbag Lodge plan as I had previously designed one very close to that concept before seeing it. My other main goal is optimal climate control with earth and the freedom that brings.

For the lay person, such as myself, deciding whether a living roof vs. a more conventional metal roof system is best in terms of interior climate control, insulation, etc. Are the benefits of an earthen roof worth the process? A living roof seems more difficult to waterproof without the costly membrane. I have lots of dirt, juniper poles and pallets. Straw bales are out of the question as they are $10-12 a bale around here. I LOVE the earthbag concept. I’m just brainstorming a bit more as I reconsider what is available in bulk and free. Thanks for all the time. The part of Texas I live can get very cold in the winter and is very hot in the summer. I’ve been talking to several friends and really turning them on to the idea of self preservation and taking back our housing needs from the commodity black hole. Keep of the fine work!

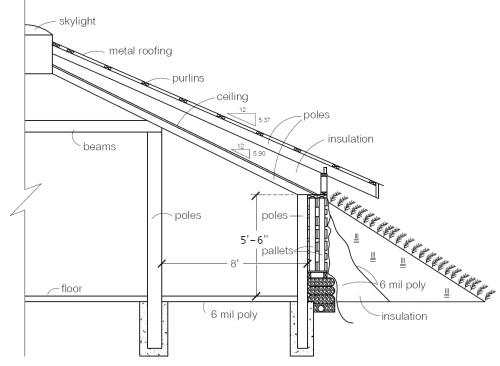

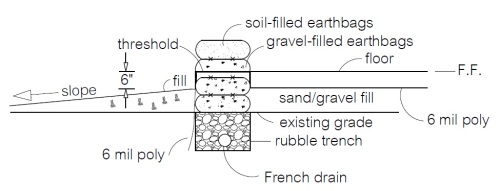

Owen: Utilizing low cost and free materials where you live is the way to go. Even though I’m a huge fan of earthbags, you always want to consider different options and decide what makes the most sense for you. Since you have lots of free pallets and rot resistant juniper poles then consider building a double pallet wall on an earthbag foundation as shown in the drawing above. This method may be a little faster than building entirely with earthbags and use fewer bags. (I’m assuming you have access to a chainsaw and posthole auger to speed the work.)

The whole process of building a roof that can withstand the heavy load of a living roof, and the time and effort for waterproofing, insulating, making the living roof AND maintaining the plants over time, which is a huge amount of work in itself, would tip the scale for me to pole roofs or framed roofs with lots of insulation, and metal roofing to collect roofwater (super important in dry areas). I suggest a double pole roof that is supported by a post and beam frame. This would be way faster to build than a living roof. It would be low cost, owner built and provide lots of space for insulation. You can achieve zero energy housing with both systems, so my vote is for a more conventional insulated roof with metal roofing.